Hightlights of The Seperating Drum for Diecast Parts

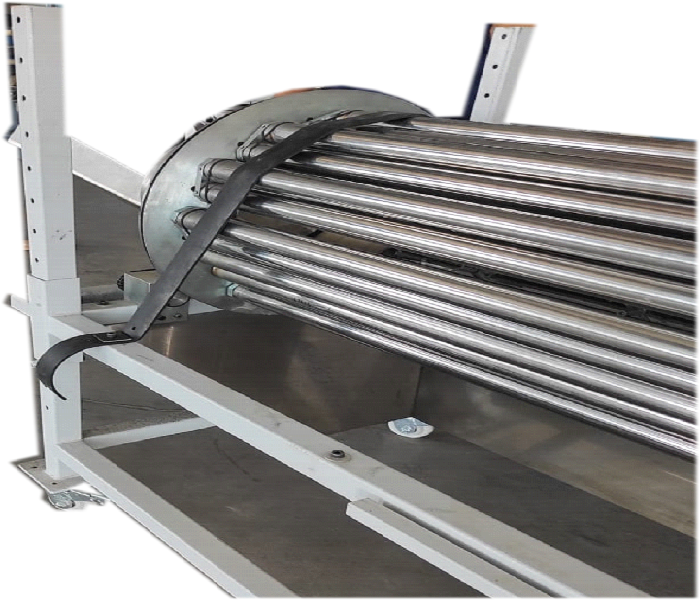

- The Separating Drums with Planetary Central Adjustment of the Types are used for an automatic separation of parts of different form and size.

- These drums are suitable for frequently changing part combinations and therefore the roller spacing can be readjusted very quickly. In case of infrequent product changes the Separating Drums with Individual Adjustment of the rollers (Types 255B to 3512B) are an economical alternative.

- The Sloughing Drums with individual adjustment of the rollers are used, when e.g. the injection moulding parts are still located on the sprue. Within this drum the parts are sloughed off the sprue, followed by their separation. All separating drums are predominantly used in the injection moulding industry and in the aluminium and zinc die-casting industry.

Benefits

- Best separating results.

- Planetary central adjustment for quick adaptation to changing product measures.

- High performance and powerful planetary gear motors.

- Separating parts do not get jammed and damaged due to the reverse rotation of the separating rollers.

- High Throughput.

- Constantly variable height and inclination of the drums.

- Simple and convenient operation Technical Data.

- Constant or continuously adjustable drum speeds.

- Separating gap continuously adjustable between 5 and 53mm (Planetary Central Adjustment).

- Reverse operation of sloughing drums with adjustable time periods for forward and reverse rotation.

- Separating length between 500 and 1,200mm.

- Rollers can be supplied in a foamed version for noise reduction.

- Swivelling feed-in chute complete with a sound absorbing polyamide coating.

- Heavy double stand underframe with four steering rollers.

- Cladding and functional sheets made of anodised aluminium or galvanised steel sheet (stainless steel on request).

- Soundproof hood (on request)